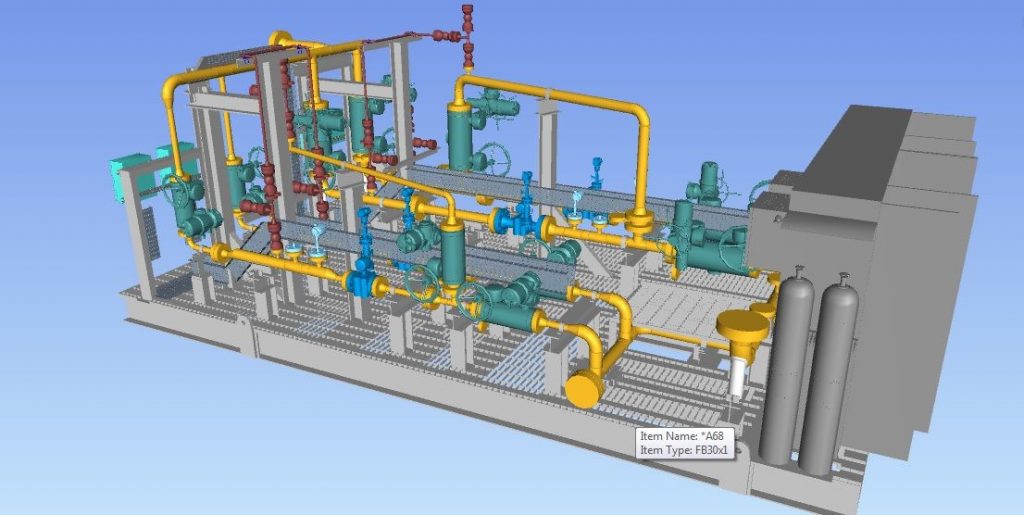

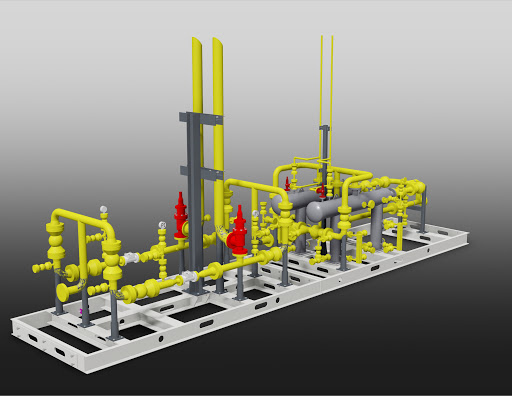

Process Skids

We work with Leading Water Treatment & Fire Supression Companies to manufacture process Skids & Fire Supression Skids for projects all over the world. Our Strict quality control & timely delivery have proven to be an essential component of these critial units.

The process flow of our Skid Manufacturing process is as follows:

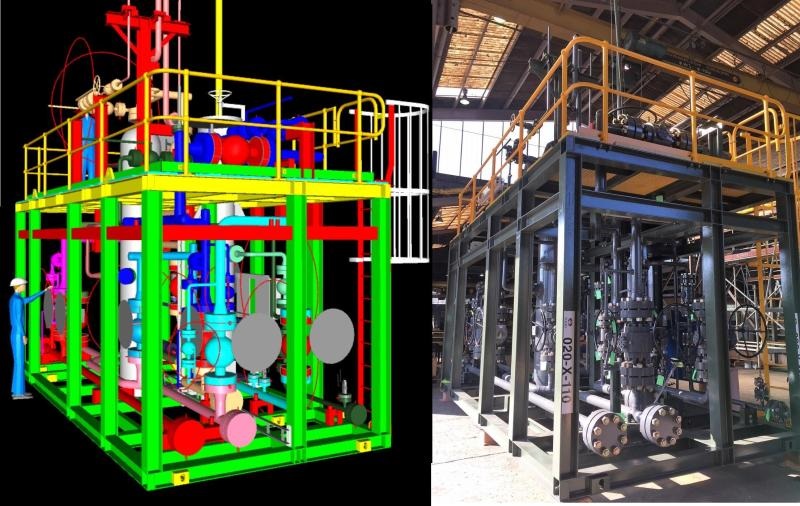

Design, Engineering, Calculations & Validation

Our experience with Tanks, Piping Systems & Structural Steel Manufacturing prove useful during the design & optimization of the various parts of any process skid. We use advanced software such as ANSYS, PV Elite, AutoCAD & Autodesk Robot to Design & Engineer the skids

Procurement

We have sucessfuly procured various grades of raw materials from specific sources as per each individual project’s specifications. Certain projects also specify the Welding consumables to be used during manufacturing of some critical components; We have, therefore, developed suppliers for consumables which are rarely available in the Middle East Region

Manufacturing

Once the manufacturing drawings are approved by our client, we proceed with the manufacturing process that is strictly controlled by our Quality Control Team. Again, our team’s experience with the manufacturing of Tanks, Piping & Steel Structures comes in handy. Manufacturing processes are carefully planned to ensure timely delivery of all projects. We also assit with manpower for the Installation of various special instruments/automated valves supplied by clients

Testing & Commissioning

We carry out systems testing in the presence of clients as per the agreed Inspection & testing Plan (ITP). Modular skids are then shipped on successful completion of the testing process